Receive-Ready Pallets/Bundles

DDC Inbound Shipping Guide

Table of Contents

Introduction:

- Delivery Distribution Centers (DDCs)

- Best Buy Business Days

- Vendor EDI Requirements

- Packaging, Environmental and Recycling Attributes

Sections:

Receive-Ready Pallets/Bundles

Published 09/28/2018, 08:49 PMQuestions about this section? Contact Dist_Ops_Support@bestbuy.com.

4.1 When to Palletize?

- If shipping (or delivering) via less-than-truckload (LTL) capacity, 100% of LTL product must be palletized.

- When eligible floor-loaded product is not safe to unload via clamp machine.

4.2 BBY-approved Pallets

- 48-inch by 40-inch GMA, made of “Grade A” hardwood, allowing four-way forklift entry.

- Pallets must be “Regular Duty” and made of hardwood:

- Withstanding weights up to 2,800 lbs.

- Wood must be sound (no decay) and square edged.

- No missing or broken top or bottom boards. o Top and bottom boards must be a minimum 5/8 inches thick.

- Spacing between top boards on must never exceed 3 ¼ inches.

- Individual units longer than 48 inches are allowed to use custom pallets, but must comply with type of wood and other pallet requirements.

Unless approved by Best Buy, all other pallet types are non-compliant.

Note: All non-approved pallet usage is subject to compliance charges.

4.3 Shipping Configuration & Orientation

4.3.1 Majors

- If banding is used, it must be made of plastic. Do not use metal banding.

- If wrap film is used, it must be completely clear and colorless.

4.3.2 TVs

- Do not ship “loose” floor-loaded product. Shipping configuration must be either palletized or bundled.

- Without exception, on each pallet (or within each bundle), only product for 1 Best Buy Purchase Order is allowed.

- Bundles are considered floor-loaded product and can be utilized only for full Truckload shipments.

- If wrap film is used, it must be completely clear and colorless.

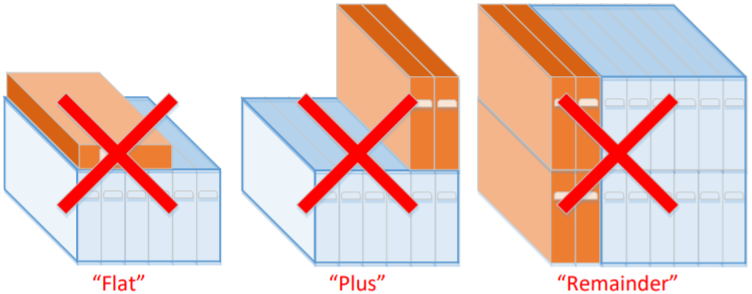

- Do not ship TVs resting “Flat” on its side. TVs must ship in the upright orientation.

- Do not ship in a “Plus” orientation. Do not ship inconsistent layer quantities.

- Do not ship in a “Remainder” (unbundled or non-approved bundle) configuration.

- Note: There is no pre-defined maximum pallet height. However, pallets must follow the required vertical trailer clearance guidelines as defined in Section 5.2.3.

4.3.3 Accessories

- Do not ship “loose” floor-loaded product. Shipping configuration must be either palletized or bundled.

- Without exception, on each pallet (or within each bundle), only product for 1 Best Buy Purchase Order is allowed.

- Bundles are considered floor-loaded product and can be used only for full Truckload shipments.

- If banding is used, it must be made of plastic. Do not use metal banding.

- If wrap film is used, it must be completely clear and colorless.

- Mixed-Model/UPC Pallets should be the exception. Consolidate like-Model/UPCs onto the fewest number of pallets. Maximizing trailer cube should not take precedence over consolidating like-Model/UPC. Excessive Mixed-Mode/UPC Pallet use can lead to receiving errors and driver detention.

- Note: There is no pre-defined maximum pallet height. However, pallets must follow the required vertical trailer clearance guidelines as defined in Section 5.2.3.

4.4 Step-by-Step Checklist – Palletizing

Do not allow product to extend (overhang) beyond any of the pallet sides. Referred to as a “Zero-Overhang” policy, the goal is to mitigate logistical stream-induced product damage and allow for safe and secure product putaway.

4.4.1 Majors

- Select BBY-approved Pallet.

- Center the ship-ready appliance unit so that product does not extend (overhang) beyond any of the pallet sides.

- Use corner/edge boards to increase vertical stacking strength, prevent damage to edges, and stabilize for transit and conveyance. Apply to all edges and extend to the full height and length.

- If banding is used to secure the shipment to the pallet, apply over corner/edge boards and down through the pallet itself. Do not apply banding without corner/edge boards, as it can cause carton damage.

- Machine application of clear film is preferable. Use clear stretch wrap (minimum of 80 gauge, recommend 3 revolutions), starting at the bottom wrap upward and around the product. This limits product separation, reduces load shifting, and any tearing of wrap eases identifying potential in-transit load tampering.

- Only for LTL shipments, seal a pallet-level packing slip on the short (40”) pallet side [Reference 6.1].

4.4.2 TVs

- If palletizing, it is recommended that TVs be bundled prior to palletization [Section 4.6.1].

- Approved TV Bundle guidelines are meant to help facilitate safe, consistent, and efficient product handling to and through Best Buy DDCs. The goals are to reduce safety risk, reduce damage, and increase efficiency in supply chain processing.

- Aside from above benefits, application provides protection from elements so that the sellable-unit is clean and presentable to customers.

4.4.3 Accessories

- Select BBY-approved Pallet.

- Use a corrugate sheet underneath the bottom-layer for protection and stability.

- Stack like-Model/UPC boxes in adjoining arrangement.

- Consolidate like-Model/UPC product to as few pallets as possible.

- Per pallet, consolidate like-Model/UPC into (vertically adjacent) layers.

- If layers are not feasible, consolidate into logical adjoining arrangement.

- Orient carton shipping labels with the following on-pallet considerations:

- Collectively orient small-cube product to face one side of the pallet.

- Orient other product so that all labels face out towards the nearest side.

- Use a corrugate sheet on every third layer, when possible, to distribute weight evenly.

- When necessary, use corner/edge boards to increase vertical stacking strength, prevent damage to edges, and stabilize for transit and conveyance. Apply to all edges and extend to the full height and length.

- If banding is used to secure the shipment to the pallet, apply over corner/edge boards and down through the pallet itself. Do not apply banding without corner/edge boards as it can cause carton damage.

- Machine application of clear film is preferable. If not, use clear stretch wrap (minimum of 80 gauge, recommend 3 revolutions), starting at the bottom wrap upward and fully encompassing the product. This limits product separation, reduces load shifting, and any tearing of wrap eases identifying potential in-transit load tampering.

- Seal a pallet-level packing slip on the short (40”) pallet side [Reference 6.1].

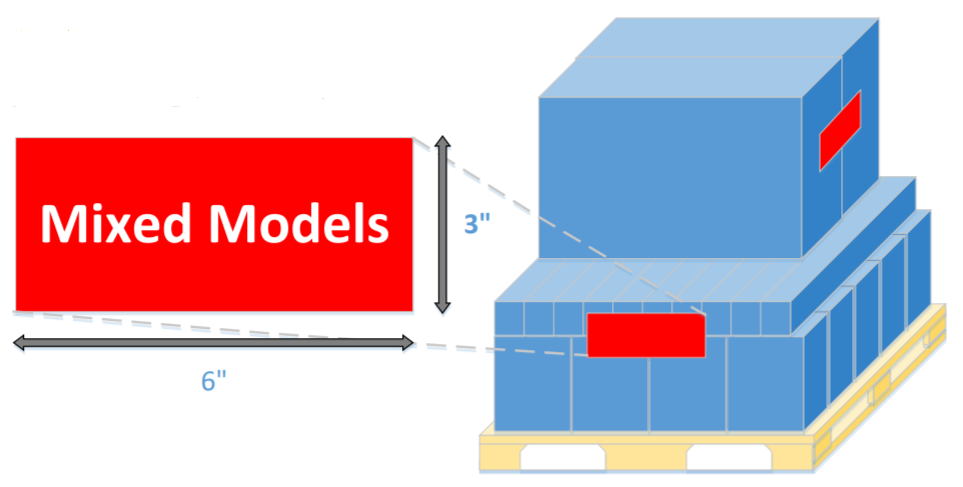

4.5 If Constructing "Mixed-Model/UPC Pallets"

On each pallet, consolidate like-Model UPC product into (adjacent) layers.

Per pallet, on the exterior of any stretch wrap film, colored placarding is required and should be placed on (at minimum) 2 adjacent sides.

Placarding must call out “Mixed UPCs”, “Mixed Models”, or some derivation of the like.

BBY placard recommendations:

- Colored placarding that is no smaller than 3 inches tall by 6 inches wide

- A Font Size greater than 72 point and in BOLD

4.6 Step-by-Step Checklist - Bundles

4.6.1 TVs

- Approved TV Bundle guidelines are meant to help facilitate safe, consistent, and efficient product handling to and through Best Buy DDCs. The goals are to reduce safety risk, reduce damage, and increase efficiency in supply chain processing.

- If palletizing TVs, it is recommended that TVs be bundled prior to palletization (see below steps). Aside from above benefits, application provides protection from elements so that the sellable-unit is clean and presentable to customers.

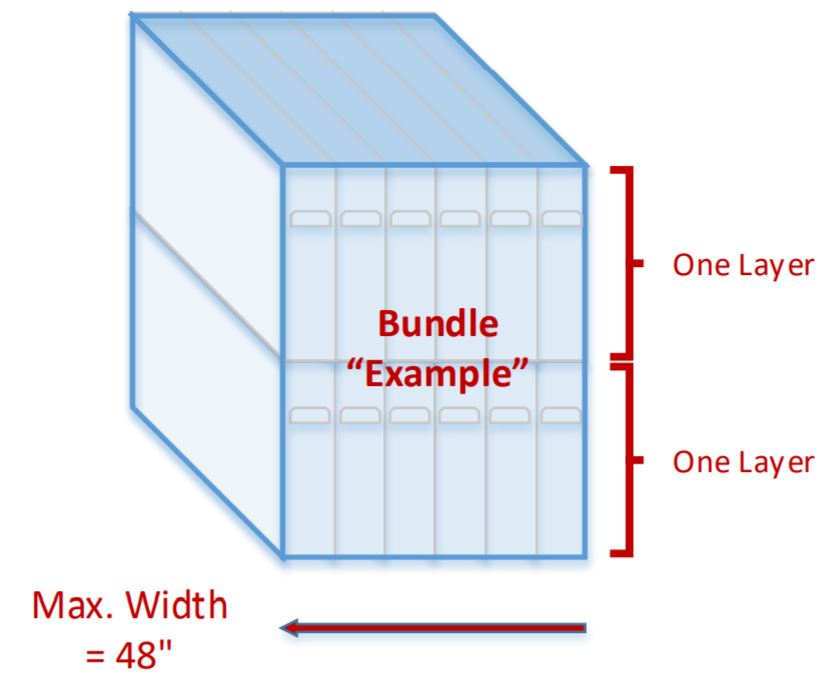

- Bundles must be built in full, consistent, and pre-defined layer quantities. To align on (BBY-ordered, Vendor-shipped) layer quantities, partner with BBY Demand Planning. Each layer should be built up to (but not exceeding) 48 inches in width.

- Banding of TV Bundles is not permitted.

- Step-by-Step Checklist - Bundling TVs

- Start with a multi-use plastic slip sheet underneath the bottom-layer for product protection and stability. Of note, Best Buy does not have slip sheet unloading equipment.

- Align like-UPC product together. Initially orient the default front-side of all TVs in the same direction.

- Bundles must be built in full, consistent, and pre-defined layer quantities. *To align on (BBY-ordered, Vendor-shipped) layer quantities partner with BBY Demand Planning.*

- The two outermost units’ default front-side(s) must face inward towards the middle of the bundle. See graphic illustration below.

- Use corner/edge boards to increase vertical stacking strength, prevent damage to edges, and stabilize for transit and conveyance. Apply to all edges and corners, and extending the full height and length of the product.

- Use sufficient clear film/wrap to reduce load shifting during transport and limit product separation. Do not wrap individual (or sub-sections of units).

4.6.2 Accessories

- Bundles must contain only 1 like-Model/UPC. To avoid receiving errors, do not build Mixed-Model/UPC Bundles. Regardless of any “Mixed Models” placarding application, bundles are always assumed as like-Model/UPC bundles.

- Vendor should assume that all bundled product will be unloaded from the trailer via clamp truck.

- If product packaging cannot withstand clamp unloading, product must be palletized on a BBY-approved pallet.

- Immediate no-touch/quick-clamp bundle orientation needs to exist all throughout the trailer.

- Start with a multi-use plastic slip sheet underneath the bottom-layer for product protection and stability. Note: Best Buy does not have slip sheet unloading equipment.

- Always position like-Model/UPC boxes upright and in the same product orientation (facing the same direction).

- Build the bottom layer into a recommended (minimum) 3 feet by 3 feet bundle base.

- Excluding height dimension, do not exceed 82” on any bundle dimension.

- If the manufacturer’s recommendations will allow, continually stack boxes on top of the bottom layer.

- Do not stack beyond manufacturer’s recommendations.

- When possible, create even product layers.

- When necessary, use corner/edge boards to increase vertical stacking strength, prevent damage to edges, and stabilize for transit and conveyance. Apply to all edges and extend to the full height and length.

- If banding is used to secure the product bundle, apply over corner/edge boards. Do not apply banding without corner/edge boards as it can cause carton damage.

- Machine application of approved film is preferable. If not, use clear stretch wrap (minimum of 80 gauge, with a recommended 3 revolutions), starting at the bottom wrap upward and fully encompassing the product. This limits product separation, reduces load shifting, and any tearing of wrap eases identifying potential in-transit load tampering.