Receive-Ready Cartons

DDC Inbound Shipping Guide

Table of Contents

Introduction:

- Delivery Distribution Centers (DDCs)

- Best Buy Business Days

- Vendor EDI Requirements

- Packaging, Environmental and Recycling Attributes

Sections:

< Back

Receive-Ready Cartons

Published 09/28/2018, 06:07 PM

Last Update 07/01/2022, 05:01 PM

Questions about this section? Contact Dist_Ops_Support@bestbuy.com.

3.1 Reliability & Design

3.1.1 Majors

- In-the-box protective framing should encompass all corners and edges of the product.

- Product packaging and protective frame must:

- Enable Best Buy to off-load product, from trailer, in a safe and efficient “Receive-Ready” manner.

- Protect the product from, while allowing for, multiple clampable moves.

- Sustain a minimum like-UPC stack height of 16 feet (4.9 meters) without incurring product or carton damage.

- Not warp or loose integrity in high humidity and/or high-to-low temperature environments.

- Adequately protect the sellable-unit at the contact points from use of hand-truck during home-delivery.

- If hand-access holes exist, they must maintain functional durability under repeated use.

3.1.2 TV's

- In-the-box protective framing should encompass all corners and edges of the product.

- Product packaging and protective frame must:

- Sustain these required minimum like-UPC unit-stack heights without incurring product or carton damage:

- If TV size is less than or equal to 60 inches, required minimum stack height is 6 units high.

- If TV size is greater than 60 inches, required minimum stack height is 4 units high.

- Not warp or loose integrity in high humidity and/or in high-to-low temperature environments.

- Sustain these required minimum like-UPC unit-stack heights without incurring product or carton damage:

- Hand-access holes must exist on each of the two narrow side-panels, and they must maintain functional durability under repeated use.

- To help facilitate ease of customer unboxing, carton design should include unboxing methodology on the carton’s exterior design. For more detail around design requirements, email your Best Buy Business Team contacts.

3.1.3 Accessories

- All shipping cartons (MP & IP) must be made of rigid recyclable corrugate.

- Carton packaging and cushioning material must be able to maintain integrity and be free of damage through [1] typical rigors in transit, [2] staging in high humidity and/or high-to-low temperature environments.

- Do not use banding on individual cartons alone, as it can cause tearing to packaging.

- Use strong 3” wide tape designed for shipping.

- Apply H-Taping method to seal all edges and seams. [1] Apply once, parallel to, and on-and-along each center seams. [2] Apply two strips of tape across both edge seams.

- Do not apply tape perpendicular to flap seam.

- Any other taping methodology will be reviewed as a potential pilferage.

- Adherence to National Motor Freight Classification (NMFC) standards is expected. See www.nmfta.org

3.2 Case Pack Quantity [CPQ] Approval Process

3.2.1 Accessories

- Prior to item induction, discussions around the following considerations should take place with Best Buy Demand Planning:

- CPQ is the BBY purchase order unit of measure and must align with the carton shipping configuration.

- If inners cartons exist, they are typically the DC-to-store replenishment unit of measure.

- CPQ Change Request (change existing CPQ):

- Prior to shipping a new CPQ configuration, vendors must email both the BBY Demand Planning Analyst and their corresponding BBY Demand Planning Manager to request CPQ approval.

- If email-approval is received, vendor must initiate a firm stop date to discontinue shipments of the old CPQ.

- Prior to shipping the new CPQ, the vendor will need to make updates via PDM with the new CPQ, GTIN-14 barcode, and adjusted dimensions/weights.

3.3 Carton Configuration

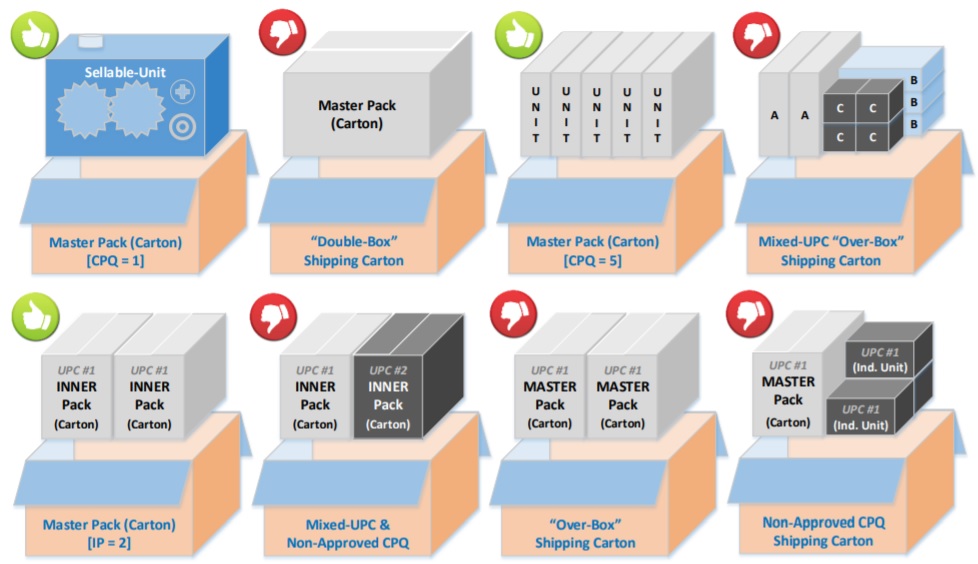

3.3.1 Accessories

- Within an individual shipping carton…

- Only product of 1 unique UPC is allowed. Do not box together mixed-UPC product.

- Fulfillment to only 1 unique Best Buy Purchase Order is allowed.

- Do not double-box or over-box cartons.

- Example: Do not box any Master Pack cartons within a larger shipping box.

- Only acceptable application: An approved Master Pack carton containing multiple Inner Pack cartons.

- A Master Pack is the largest BBY-approved shipping carton containing a pre-defined (CPQ) number of sellable-units.

- Shipping in less than (or more than) the BBY-approved case pack quantities is not acceptable.

3.4 On-Carton Information

3.4.1 Majors & TV's

- The sellable-unit carton should have the following attributes:

- Vendor Name and/or Vendor Icon

- Product Name or Model #

- Iconography – When applicable and side-specific [Section 3.8]

- Product Orientation – Side-specific product orientation (i.e. Front, Back, Side)

- In-Box and Out-of-Box Dimensions

3.4.2 Accessories

- For accurate and timely receiving, these 5 Critical Attributes are required on each Master Pack carton:

- Vendor Name and/or Vendor Icon

- Product Name or Model #

- Best Buy (Alpha) PO Number

- Case Pack Quantity [CPQ] – Required if the number of sellable-units (CPQ) >1. Not required, if CPQ = 1.

- Trade Item Number & Barcode – Along with human readable number, barcode must be machine-readable from a distance of 4 feet. Do not mark through barcode. If the Master Pack carton’s sellable-unit quantity (CPQ) is:

- > 1, affix applicable ITF-14 barcode to the Master Pack carton.

- = 1, affix applicable UPC-A barcode to the Master Pack carton.

- If any of the aforementioned is not present on either the Carrier Shipping Label or the on-carton (Master Pack carton) design, create “Receiving Labels” that will fulfill the 5 Critical Attributes.

- To avoid a poor customer experience, do not affix labels directly onto the surface of sellable-units.

- When possible, labels should either be placed on the outside surface of non-sellable cartons or exterior surface of wrap/film. Labels should not cross any carton seams or edges.

- Currently, Serial Shipping Container Codes (SSCC-18, aka UCC-128) cannot be used at Best Buy DDCs. Best Buy enhancements are being considered to leverage ASN capability. In anticipation, it is advised that forward-looking vendors implement this feature within their shipping process.

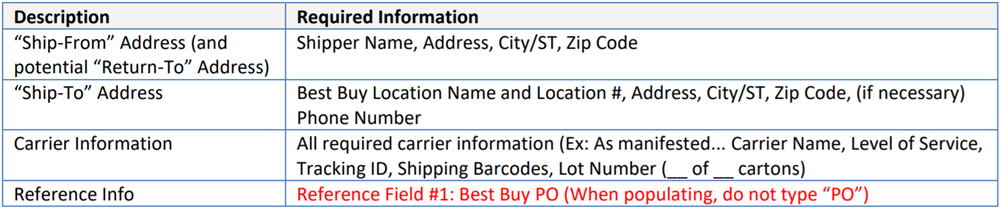

3.5 Carrier Shipping Labels

If shipping LTL, for each pallet, affix carrier shipping labels on all 5 exposed sides (4-sides and on top).

When possible, labels should either be placed on the outside surface of non-sellable cartons or exterior surface of wrap/film. Labels should not cross any carton seams or edges.

Ship-To Address must follow the Best Buy location naming convention (ex: “Best Buy DDC #74 – St. Louis”):

3.6 Receiving Labels

3.6.1 Majors & TV's

- For accurate and timely receiving, vendor-generated Receiving Labels should contain the Best Buy (Alpha) PO Number

- Label Size: Vendors must gauge appropriate size, but 4-inches wide by 2-inches tall is preferable.

- Placement of unobstructed label:

- Do not cover: Iconography, Product Orientation, In-Box and Out-of-Box Dimensions, or Carrier Shipping Label.

- For product or pallet/unit loads that are greater than 60 inches high, the label should be placed no higher than 4-6 inches from the top, and no lower than 32-36 inches from the bottom.

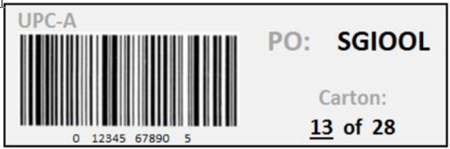

Below is a suggested example for Receiving Labels:

3.6.2 Accessories

- Vendor-generated Receiving Labels are only required if the 5 Critical Attributes (mentioned above) are not available.

- Label Size: Vendors must gauge appropriate size, but 4-inches wide by 3-inches tall is preferable.

- Placement of unobstructed label:

- Where applicable a minimum of 2 inches from any edge of each carton. For product or pallet/unit loads that are greater than 60 inches high, the label should be placed no higher than 4-6 inches from the top, and no lower than 32-36 inches from the bottom.

- Below are suggested examples for Receiving Labels. Format is not as important as the actual content.

3.7 Box Strength Recommendations

3.7.1 Accessories

3.8 Iconography

3.8.1 Majors

- Suggested side-specific special handling iconography must be visible on the exterior of each unit.

- Iconography must translate universally between customers and within Best Buy’s end-to-end supply chain.

- At minimum, Best Buy requires the following iconography:

| Iconography | Special-Handling Interpretation |

|---|---|

| Forklift / NO Forklift | Forklift use is/isn’t eligible on the specific side of the pallet that the icon is affixed. |

| Clamp / NO Clamp | Facing the specific side that the icon is affixed, squeeze clamp use is/isn’t product safe. |

| Hand Truck / NO Hand Truck | Hand Truck use is/isn’t eligible on the specific side of the product that the icon is affixed. |

| This Way Up Arrow | Indicates the direction that which the product needs to be oriented during shipping and storage. |

| Maximum Stack Height | The number on the icon indicates the maximum (and total) number of cartons that can be stacked on top of each other. |

3.8.2 TV's

- Best Buy is looking to drive consistent TV-specific icons across all vendors and models. For the most recent iconography standards, reach out to your Best Buy Business Team contacts.

- Upon request, Best Buy standard icon assets can be provided. Ultimately, iconography must translate universally with customers and within Best Buy’s end-to-end supply chain.

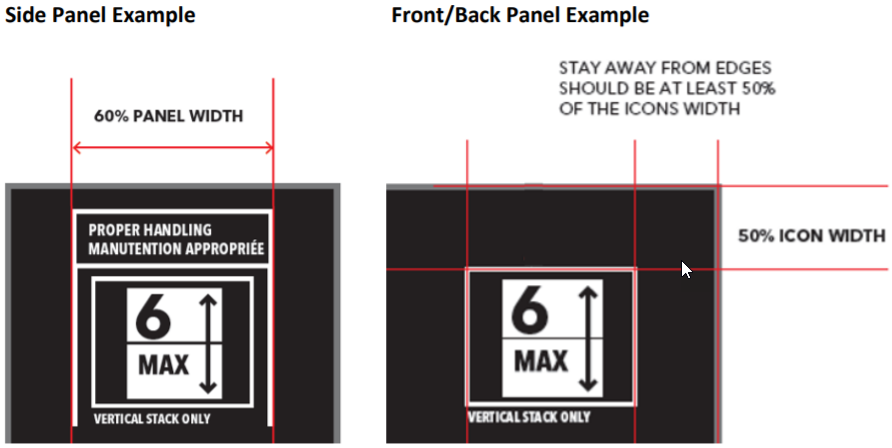

- Required “Stack Height Icon” use and application must be as follows:

- Side Panels (Example on the left)

- Icon must be horizontally centered.

- Icon size must be a minimum width of 64 mm ▪ Icon size must not exceed 60% of panel width.

- Front and Back Panels (Example on the right)

- Preferred placement is in the upper right-hand corner.

- Icon size must be identical to that of the side panels.

- The space between the icon and any edge must exceed 50% of the icon’s width.

- Side Panels (Example on the left)